Welcome!

Modern technologies such as robotics, autonomous cars, and AI-driven electronics ignite the imagination for a better world, prompting me to continue through a winding research career. I started with robotics in academia, and am currently running the engineering functions at Arieca, a startup that utilizes materials science to help keep electronics cold and running efficiently. This website summarizes my career in a quick read. The journey is always more interesting than the destination; so for the remainder of your time on this page, I encourage you to scroll around, click some of the links, and see where your mind takes you. Otherwise, if you're in a hurry and don't know why, the tabs at the top can help you find what you're looking for.

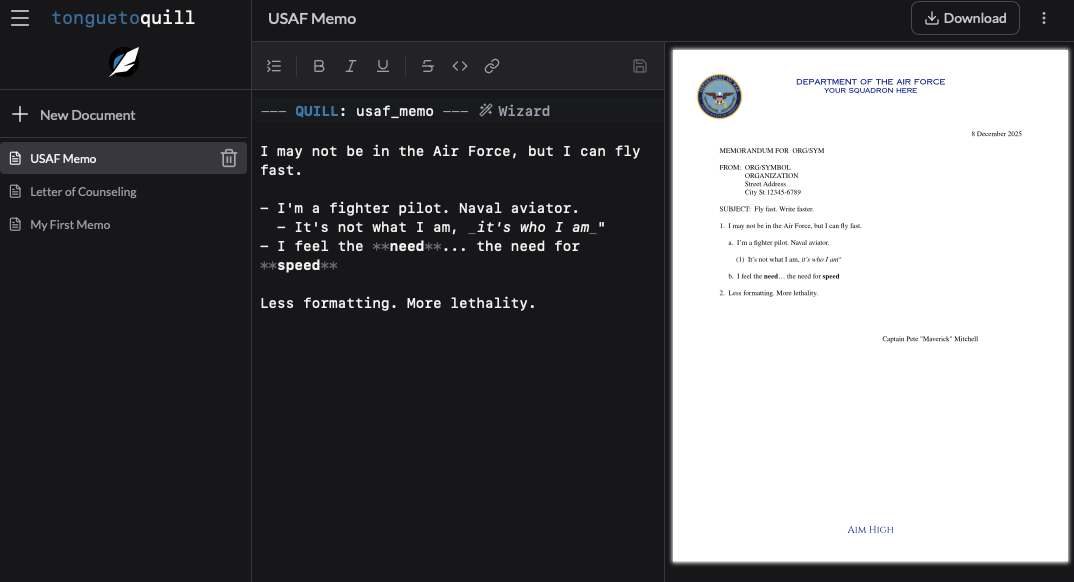

If you find this page interesting, send me a note on LinkedIn. I'm also looking for feedback on DoctorSpeak, a smart diary that helps people understand their health; and my friend's app Tongue to Quill, making it easy to create PDF documents that perfectly conform to companies' rules, with initial applications in the DoD.

Thanks for visiting!

Dr. Dyl

Research

TL;DR

I started with a combined degree with a B.S. in mechanical engineering and M.S. in agricultural engineering with the ABE Automation and Robotics Lab at Iowa State University, developing robots to improve data throughput in agronomy, to help farmers improve yield and decrease environmental impact. I then completed a PhD with the Faboratory at Yale University, and served as a NASA Space Technology Research Fellow, tackling challenges in soft robotics, where I used flexible materials to enable new functionalities in robots for both Earth and space. The overarching theme of my dissertation was embedding functionality into "robotic skins" that can allow engineers to make use of the relatively unused surfaces of robots, while also serving as a multi-functional robotic prototyping platform for resource-constrained applications (think: spacecraft, dense urban areas, remote research facilities).

Since joining Arieca in April 2022, I have been contributing to the commercialization of liquid metal embedded elastomers (LMEEs) to solve problems in thermal management, primarily for the automotive and semiconductor industries. My current role is the Vice President of Hardware R&D, where we test our thermal interface materials in situations that mimic our end-users' setups, such as smartphones, laptops, PC's, etc.. I am co-PI on collaborations with Carmel Majidi's Soft Machines Lab at Carnegie Mellon University (CMU), where we explore emerging applications of LMEEs, ranging from bodyheat-powered electronics to high-performing interface materials for aerospace applications.

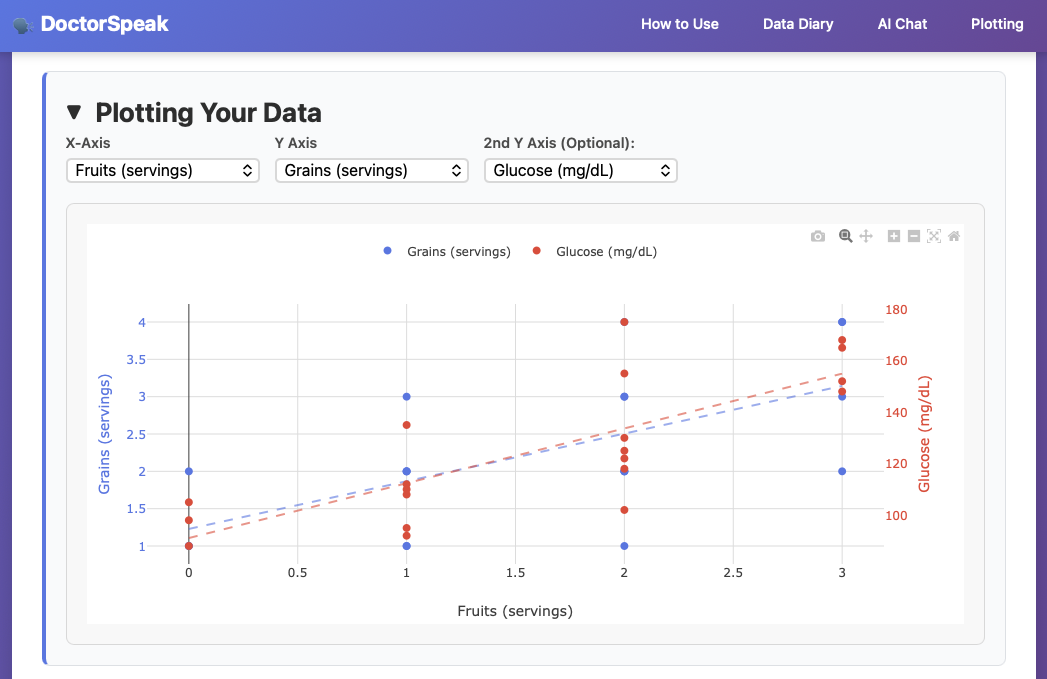

Additionally, I stay active in the soft robotics and stretchable electronics communities through joint publications (see Google Scholar) and organizations such as the Nano-Bio Materials Consortium. You can check out my personal projects on this website (I'll start pushing simple web applets here) or on GitHub. For example, I just pushed a simple data plotter to this site to play around with. The original idea is to help patients plot their health symptoms and show them to their doctors and communicate what's going on with simple data-driven techniques but minimal statistical knowledge required by the user. This version was coded using Windsurf and its incredible AI integrations, so it works but is probably not following best web practices. Nonetheless, the Google login should be secure since it's done directly with Google's authentication service - no passwords are stored on my server. If you've got some ideas of little applets to build, drop me a line!

Each new chapter in life brings exciting changes, new opportunities, and surprising discoveries. We can only live in the most recent one, building upon the experiences, memories, and skills gained in each prior chapter. This reverse-chronological ordering reflects this reality in a clean ordering; in reality, the journey was anything but linear.

Chapter 3: Thermal Interface Materials at Arieca

April 2022 - Present

After my PhD, I wanted to gain first-hand experience in startups, to see how companies are born. Like a star, they are at first just a nebulus idea, then they condense into a shining star to shed light on how new technology can solve contemporary problems. So, I joined Arieca around its series A close, as the company was getting ready to scale up some key customer engagements and government contracts. Arieca was co-founded by Navid Kazem and his PhD advisor, Carnegie Mellon University professor Carmel Majidi. They were investigating adding liquid metals to polymers to make multifunctional composites, including stretchable circuits and thermally conductive rubber (coining the terms "thubber" and liquid metal embedded elastomers, or LMEE). In 2018, they incorporated Arieca to commercialize LMEE, pursuing government research grants and B2B sales to partners primarily in the semiconductor and automotive industries.

Currently, I serve as the Director of Hardware R&D, where I lead an engineering team that studies how our thermal interface materials perform in end-use hardware setups, to aid our customers in their material qualification and pathfinding processes. Key engagements include joint research with ROHM Semiconductor and scaling up production with Nissan Chemical.

Additionally, our team conducts research into how our materials could solve fundamental problems in adjacent industries and emerging applications, through government contracts as well as commercial partnerships. This includes collaboration at CMU, where we make bodyheat powered wearable electronics (funded by the Nano-Bio Materials Consortium, where I was recently appointed to the Technical Advisory Council). Our recent Advanced Functional Materials paper showed technical feasibility of powering a photoplethysmography (PPG) sensor for continuous monitoring of heartrate and blood oxygen without a battery.

Chapter 2: Soft Robots at Purdue and Yale University

Aug 2016 - April 2022

In Fall 2016, I joined the Faboratory at Purdue University with Prof. Rebecca Kramer-Bottiglio, to work on soft robotics. We applied compliant materials to robots, toward the goals of increased safety and dexterity. I then moved with the lab to Yale University, where I embedded robotic functionalities into thin skins, and designed shape changing robots. In Spring 2021, I received the Henry Prentiss Becton Prize for my research, and defended my dissertation in December 2021. I then stayed on as a post-doctoral researcher until I moved to Arieca in April 2022, formally receiving my PhD diploma in May 2022. All major projects led to peer-reviewed publications (see below), with my favorites described in detail below, along with selected publications:

- Embedding actuation and sensing into planar "robotic skins" to turn passive deformable bodies - including foam, clothing, and stuffed animals - into robots (Figure 1, Video 1, and paper in Science Robotics). These multi-functional robots could serve as lightweight tools for space missions, while also finding applications as wearable exosuits or assistive devices here on Earth. Additional coverage can be found on the web, including at Smithsonian.com NationalGeographic.com (link a victim of link rot).

Figure 1: Robotic Skins are planar sheets with integrated sensing and actuation. When applied to deformable bodies, a variety of motions and functions can be achieved, depending on the orientation of the skins. Video 1. In this summary video produced by Yale, we show how to remove robotic skins and apply them to various deformable objects to "roboticize" them. The concept could find applications in space missions, whereby a single set of robotic skins could accomplish a variety of functions on different missions by leveraging in-situ resources, reducing the total number of robots needed at the landing site or spaceship.

- Making stretchable "jamming skins" that change their stiffness and stretchability upon application of a vacuum (Figure 2, Video 2, and paper in Advanced Functional Materials). Very few soft robots can switch their stiffness to interact with the environment; those that can stiffen often require significant design constraints (such as a large volume of stiffness-changing material) which limit their applicability. By embedding strong jamming capabilities into thin sheets, I aimed to allow stiffness-changing capabilities to be added to the full range of soft robots. After I solved the major mechanical and manufacturing challenges, the final jamming skins are now scalable and can be readily integrated into other future soft robots.

Figure 2: Jamming skins can be applied to the surface of deformable objects to provide support, or be reconfigured to create structures and tools on-demand. Upon application of a vacuum, the skins transition from flexible and stretchable sheets (no added shading) to stiff surfaces (cyan shading). Applications shown in the bottom row, from left to right: continuum manipulator with on-demand joints, reconfigurable table, sculptable reservoir for holding liquids. Video 2. By stretching an inactive jamming skin, then pulling a vacuum when it's in the desired shape, various structures and tools can be created. Here, we highlight this capability by forming the skin around a 3D printed face, creating a temporary rigid mask. Traditional jamming membranes could only bend about one axis, making such complex shapes impossible.

- Sensors for impact-resistant, lightweight "tensegrity" robots (see bottom of Figure 1, our review paper in Soft Robotics or Vytas Sunspiral's NASA 360 talk). Most of my work in this area used short rods (10-30 cm) connected to stretchable sensors and pneumatic actuators, inspired by NASA Ames, including my NASA Space Technology Research Fellowship mentor Massimo Vespignani, who has demonstrated a human-sized "Super Ball Bot" that can absorb heavy impacts and even survive drops of several meters. These tensegrities have potential as exploratory robots that can exploit steep terrain changes, rather than navigating around them.

- Making shape-changing robots with talented collaborators from Yale, the University of Vermont, and Tufts University. Example robots include our cable-driven shape-changing robot and our robot that changes shape to locomote in different environments. Shi En Kim concisely summarized the project, along with the robotic skins project, on Massive Science.

- My final PhD projects were to create variable-stiffness robotic skins (paper in RA-L), and stretchable circuits with embedded sensors, to allow them to sense their shape (Video 3; paper in Advanced Intelligent Systems). The skins had onboard orientation sensors and stretchable sensors (similar to in the OmniSkins project, above), and could relay their data to an external PC. Coupled with stretchable onboard computation (under review), we envision future systems that can sense their own shape in real time, enabling distortion-free flexible displays, smarter soft robots, and intelligently adaptive wearable electronics.

Chapter 1: Agricultural Robotics at Iowa State

May 2014 - Aug 2016

During my concurrent degrees at Iowa State University (B.S. Mechanical Engineering and M.S. Agricultural Engineering, with thesis), I worked with Lie Tang on developing robotic systems and image-processing pipelines for data collection during the entire plant life-cycle. This data is useful for improving crop yield and studying the effects of various environmental parameters on plant health.

At first, I assisted with data collection and mechanical design (including the stand analyzer for Dr. Tang's startup, FieldRobo LLC), culminating in my masters' project where I led a small team (a few undergraduates and masters' students) to design and program robots to fulfill the goals of the broader projects. The most sophisticated one (prototype shown below in Figure 3), for the Enviratron project, was a mobile rover with a robot arm and a Kinect V2 3D camera for collision-free probing during use with researchers' specified instruments, such as a fluorometer. We additionally created a slender and compact field robot for 15% of the cost of the commercial alternative, allowing us to collect data on crops, such as corn and soybeans, that are grown in fields with narrow row spacing that conventional field robots could not navigate.

Selected Presentations

Occasionally I speak at conferences, workshops, university courses, etc. about research, startups, and life after graduate school. Periodically, these get recorded. I find it fun to look back on what I was thinking at a particular moment in time, and hope you can learn a thing or two from the ones added here (more coming soon).

Latest Publications

See Google Scholar for an up-to-date and complete list. Here, I have uploaded my co-authored papers, including supplementary PDFs and videos for several of them.

2025

- A. Wertz, D. Shah, and C. Majidi, "Soft Transducers With Notch Filters for Spatially Distributed Strain Sensing," IEEE Sensors J., vol. 25, no. 20, pp. 37702–37713, Oct. 2025, doi: 10.1109/JSEN.2025.3607761.

- C. Rossetti, D. Shah, L. Russell, T. Yamashiki, and N. Kazem, "Reliability Testing of Liquid Metal Embedded Elastomers for Power Modules," in PCIM Conference 2025; International Exhibition and Conference for Power Electronics, Intelligent Motion, Renewable Energy and Energy Management, VDE, 2025, pp. 404–410.

- Z. Jiang, D. Shah, H.-J. Yang, and S. Sarkar, "Kinematic Modeling in Soft Robots: System Identification and Uncertainty Quantification," July 10, 2025, arXiv: arXiv:2507.07370. doi: 10.48550/arXiv.2507.07370.

- M. Zadan et al., "MXene-Coated Liquid Metal Nanodroplet Aggregates," Langmuir, vol. 41, no. 13, pp. 8834–8841, Apr. 2025, doi: 10.1021/acs.langmuir.5c00173.

- R. S. Annam, L. Russell, C. Rossetti, D. Shah, and N. Kazem, "Effect of Surface Roughness on the Performance of Thermal Interface Materials," in 2025 41st Semiconductor Thermal Measurement, Modeling & Management Symposium (SEMI-THERM), IEEE, 2025, pp. 162–166.

2024

- R. Baines, D. Shah, J. Marvel, J. Case, and A. Spielberg, "The need for reproducible research in soft robotics," Nat Mach Intell, pp. 1–2, Jul. 2024, doi: 10.1038/s42256-024-00869-9.

- J. Gelorme, N. Kazem, K. Feller, H. Mea, D. Shah, A. Kerr, V. Singh, "Thermal interface material, an integrated circuit formed therewith, and a method of application thereof," US12027442B1, Jul. 02, 2024.

- N. Kazem, D. S. Shah, J. Gelorme, H. J. Mea, and K. D. Feller, "Method of deposition of a thermal interface material onto a circuit assembly and an integrated circuit formed therefrom," US20240203754A1, Jun. 20, 2024.

- J. Jeong, I. Kim, Y. Choi, S. Lim, S. Kim, H. Kang, D. Shah, R. Baines, J. Booth, R. Kramer-Bottiglio, S.Y. Kim, "Spikebot: A Multigait Tensegrity Robot with Linearly Extending Struts," Soft Robotics, vol. 11, no. 2, pp. 207–217, Apr. 2024, doi: 10.1089/soro.2023.0030.

- K. Feller, D. Shah, L. Russel, and N. Kazem, "Liquid Metal Embedded Elastomers (LMEE) as Low-BLT Thermal Interface Materials," in 2024 40th Semiconductor Thermal Measurement, Modeling & Management Symposium (SEMI-THERM), Mar. 2024, pp. 1–4.

- M. Zadan, A. Wertz, D. Shah, D. Patel, W. Zu, Y. Han, J. Gelorme, H. Mea, L. Yao, M. Malakooti, S. Ko, N. Kazem, C Majidi, "Stretchable Thermoelectric Generators for Self-Powered Wearable Health Monitoring," Advanced Functional Materials, vol. n/a, no. n/a, p. 2404861, doi: 10.1002/adfm.202404861.

- R. Kramer-Bottiglio, S. Liu, D. Shah, and L. M. S. Botero, "Biphasic material and stretchable circuit board," US11937372B2, Mar. 19, 2024.

- D. S. Shah, S. J. Woodman, T. L. Buckner, E. J. Yang, and R. K. Kramer-Bottiglio, "Robotic Skins With Integrated Actuation, Sensing, and Variable Stiffness." IEEE Robotics and Automation Letters, vol. 9, no. 2, pp. 1147–1154, Feb. 2024, doi: 10.1109/LRA.2023.3337702. Supplementary Videos: S1 - PET VSRS Closed Loop Locomotion, S2 - Multi-module PET VSRS Locomotion, S3 - Mesh VSRS Locomotion, and S4 - Mesh VSRS Manipulator.

2023

- D. Shah, S. Woodman, L. Sanchez-Botero, S. Liu, and R. Kramer-Bottiglio, "Stretchable Shape-Sensing Sheets." Advanced Intelligent Systems, vol. n/a, no. n/a, p. 2300343, doi: 10.1002/aisy.202300343. Supplementary Information, S1 - Estimation of 3D Space Curves, S2 - Estimating Surface Contours on Pneumatic Bladders.

- R. Bottiglio, S. Liu, D. Shah, and L. M. S. Botero, "Biphasic material and stretchable circuit board," US20230141247A1, May 11, 2023.

2022

- L. Sanchez-Botero, D. S. Shah, and R. Kramer-Bottiglio, "Are Liquid Metals Bulk Conductors?." Advanced Materials, vol. 34, no. 26, p. 2109427, 2022, doi: 10.1002/adma.202109427.

See Earlier Publications

2021

- D. Shah, J. Booth, R. Baines, K. Wang, M. Vespignani, K. Bekris, R. Kramer-Bottiglio, "Tensegrity Robotics." Soft Robotics, Oct. 2021, doi: 10.1089/soro.2020.0170.

- B. Yang, R. Baines, D. Shah, S. Patiballa, E. Thomas, M. Venkadesan, R. Kramer-Bottiglio, "Reprogrammable soft actuation and shape-shifting via tensile jamming." Science Advances, vol. 7, no. 40, p. eabh2073, 2021, doi: 10.1126/sciadv.abh2073.

- L. Xiang et al., "Robotic Assay for Drought (RoAD): an automated phenotyping system for brassinosteroid and drought responses." The Plant Journal, vol. 107, no. 6, pp. 1837–1853, 2021, doi: 10.1111/tpj.15401.

- E. Porte, T. Sipple, L. S. Botero, D. Shah, and R. Kramer-Bottiglio, "Capacitive sensor measurement rate improves by pre-stretching." in 2021 IEEE 4th International Conference on Soft Robotics (RoboSoft), Apr. 2021, pp. 412–418. doi: 10.1109/RoboSoft51838.2021.9479328.

- S. Liu, S. Y. Kim, K. Henry, D. Shah, R. Kramer-Bottiglio, "Printed and laser-activated liquid metal-elastomer conductors using ethanol/PDMS/liquid metal double emulsions." ACS Applied Materials & Interfaces, Vol. 13, No. 24, p. 28729-28736, 2021.

- S. Liu, D. Shah, R. Kramer-Bottiglio, "Highly stretchable multilayer electronic circuits using biphasic gallium-indium." Nature Materials, Vol. 20, No.6, p. 851-858 2021.

- D. Shah, E. Yang, M. Yuen, E. Huang, R. Kramer-Bottiglio, "Jamming skins that control system rigidity from the surface." Advanced Functional Materials, Vol. 31, No. 1, p. 2006915, 2021. Supplementary videos & text, including my favorite, where the skins were locked into the shape of a face.

- D. Shah, J. Powers, L. Tilton, S. Kriegman, J. Bongard, R. Kramer-Bottiglio, A soft robot that adapts to environments through shape change." Nature Machine Intelligence, Vol. 3, No. 1, p. 57-59, 2021.

2020

- J. W. Booth, O. Cyr-Choiniere, J. C. Case, D. Shah, M. C. Yuen, R. Kramer-Bottiglio, "Surface actuation and sensing of a tensegrity structure using robotic skins." Soft Robotics, 2020.

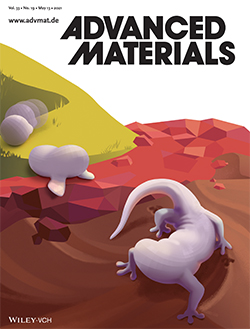

- D. Shah, B. Yang, S. Kriegman, M. Levin, J. Bongard, R. Kramer-Bottiglio, "Shape changing robots: Bioinspiration, simulation, and physical realization." Advanced Materials, Vol. 33, No. 19, p. 2002882, 2020. (Inside Back Cover Article, as shown below)

- A. Bilodeau, A. M. Nasab, D. Shah, R. Kramer-Bottiglio, "Uniform conductivity in stretchable silicones via multiphase inclusions." Soft Matter, Vol. 16, No. 25, p. 5827–5839, 2020. (Back Cover Article, as shown below)

- B. Shih, D. Shah, J. Li, T. Thuruthel, Y.-L. Park, F. Iida, Z. Bao, R. Kramer-Bottiglio, M. Tolley, "Electronic skins and machine learning for intelligent soft robots." Science Robotics, Vol. 5, No. 41, p. eaaz9239, 2020.

- S. Kim, Y. Choo, R. Bilodeau, M. Yuen, G. Kaufman, D. Shah, C. Osuji, R. Kramer-Bottiglio, "Sustainable manufacturing of sensors onto soft systems using self-coagulating conductive Pickering emulsions." Science Robotics, Vol. 5, No. 39, p. eaay3604, 2020.

- S. Kriegman, A. M. Nasab, D. Shah, H. Steele, G. Branin, M. Levin, J. Bongard, R. Kramer-Bottiglio, "Scalable sim-to-real transfer of soft robot designs." IEEE Int. Conference on Soft Robotics (RoboSoft), 2020.

2019

- Y. Bao et al., “Assessing plant performance in the Enviratron,” Plant Methods, 2019.

- S. Kriegman, S. J. Walker, D. S. Shah, M. Levin, R. Kramer-Bottiglio, J. Bongard, "Automated shapeshifting for function recovery in damaged robots." Robotics: Science and Systems, Freiburg im Breisgau, Germany, 2019.

- D. Shah, M. Yuen, L. Tilton, E. Yang, R. Kramer-Bottiglio, “Morphing Robots Using Robotic Skins That Sculpt Clay.” IEEE Robotics and Automation Letters, 2019. Supplementary Video.

2018

- J. Booth, D. Shah, J. Case, E. White, M. Yuen, O. Cyr-Choiniere, R. Kramer-Bottiglio, "OmniSkins: Robotic skins that turn inanimate objects into multifunctional robots." Science Robotics, 2018. Supplementary videos & text, plus press videos, including from National Geographic.

- J. Case, J. Booth, D. Shah, M. Yuen, R. Kramer-Bottiglio, "State and Stiffness Estimation using Robotic Fabrics." IEEE Int. Conference on Soft Robotics, Livorno, Italy, 2018.

- J. Booth, J. Case, E. White, D. Shah, R. Kramer-Bottiglio, "An Addressable Pneumatic Regulator for Distributed Control of Soft Robots." IEEE Int. Conference on Soft Robotics, Livorno, Italy, 2018.

- Y. Bao, D. S. Shah, and L. Tang, “3D Perception-Based Collision-Free Robotic Leaf Probing for Automated Indoor Plant Phenotyping,” Transactions of the American Society of Agricultural and Biological Engineers, 2018.

2017

- Y. Bao, L. Tang, and D. Shah, “Robotic 3D Plant Perception and Leaf Probing with Collision-Free Motion Planning for Automated Indoor Plant Phenotyping,” ASABE Annual International Meeting, Spokane, WA, 2017.

- D. Shah, “Development of a mobile robotic phenotyping system for growth chamber-based studies of genotype x environment interactions,” Master's thesis for Iowa State University, 2016.

- D. Shah, L. Tang, J. Gai, and R. Putta-Venkata, “Development of a Mobile Robotic Phenotyping System for Growth Chamber-based Studies of Genotype x Environment Interactions,” IFAC-PapersOnLine, 2016.

- D. S. Shah and L. Tang, "Development of an Autonomous Indoor Phenotyping Robot," ASABE Annual International Meeting, Orlando, FL, 2016.

Students

Assembling an ideal team is essential to success. I'd like to acknowledge the undergraduate students who helped with my graduate school research, as this work would not be possible without their diligence and creativity.

- Andrew Reardon. Yale class of 2021, electrical engineering. Recipient of a Fall 2019 NASA Connecticut Space Grant Undergraduate Fellowship.

- Ellen Yang. Yale class of 2020, mechanical engineering.

- Evelyn Huang. Yale class of 2020, computer science.

- Liana Tilton. Started as a high-school researcher through Hopkins High School. Washington University of St. Louis, class of 2024, Electrical Engineering and Robotics.

- Caleb Stafford. At ISU from 2012-2015. University of Iowa class of 2017, biomedical engineering.

- Layne Goertz. ISU class of 2017, mechanical engineering.

- Austin Plotz ISU class of 2015, ag systems technology, industrial technology, science and technology studies.

- Taylor Wisgerhof. ISU class of 2016, mechanical engineering.

Other

For the curious readers who make it this far, here are some resources you may find interesting.

- Like everything in life, personal finance is not confusing if you're organized. Here's a simple spreadsheet to augment what you're already doing. It includes high-level budgeting tools (for detailed budgeting, use an app or modify my sheet), recommended readings, a financial projection worksheet, and a life planning worksheet. My target audience is people who have basic financial skills and are ready to invest in public markets.

- A guide to conducting Efficient Research. This was inspired by George Whitesides' article in Advanced Materials, and contains a high-level discussion of all aspects of how to conduct research efficiently.

- A ZIP file of my favorite art (sourced from Wikipedia), generally ancient Greek sculpture and 1800's American oil painting landscapes, plus some other paintings (1800's France, Reniassance Italy).

- One of the greatest choir performances of all time: Ukuthula - Cape Town Youth Choir (formerly Pro Cantu). To fully appreciate the beauty of this song, listen using your best headphones or surround sound system. Dim the lights, turn off your other electronics and notifications, and enjoy the moment.

- Richard Hamming's lecture "You and Your Research" is a great exposition on how to ensure you're doing important work. Of course, I don't think everyone can or should try to outperform Richard Hamming, but the observations he presents can help us all do better work and keep our cycle of ideas in a continual ebb and flow, as we select a few problems to work on at a time.